Introduction of automobile wiring harness

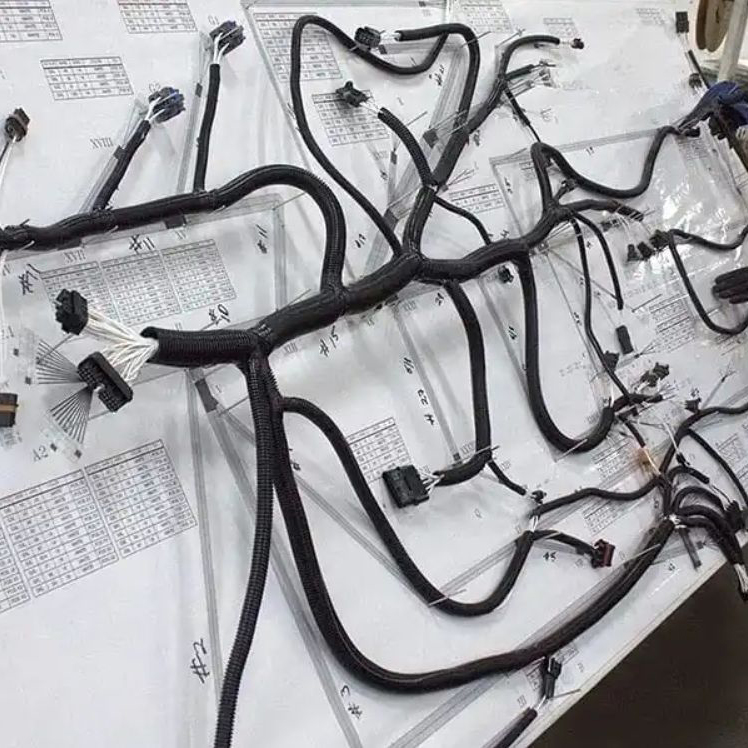

At present, there are many wiring harnesses used in automobiles, and the electronic control system is closely related to the wiring harness. The car wiring harness is the main body of the car circuit network, which connects the electronic and electrical components of the car and makes them function. It must not only ensure the transmission of electrical signals, but also ensure the reliability of the connecting circuit, supply the specified current value to the electronic and electrical components, prevent electromagnetic interference to the surrounding circuits, and eliminate electrical short-circuits.

In terms of function, the automobile wiring harness can be divided into two types: the power line that carries the power of the driving actuator (actuator) and the signal line that transmits the input command of the sensor. Power lines are thick wires that carry large currents, while signal lines are thin wires that do not carry power (optical fiber communication).

With the increase of car functions and the widespread application of electronic control technology, there will be more and more electrical components and more wires. The number of circuits and power consumption on the car will increase significantly, and the wiring harness will become thicker and heavier . This is a big problem that needs to be solved. How to arrange a large number of wire harnesses in a limited car space more effectively and reasonably, so that the car wire harnesses can play a greater role, has become a problem faced by the automobile manufacturing industry.